Check the Load-bearing Capacity of the Bottom (Tensile) Truss Chord

Objective: Check the calculation of the resistance of connections.

Task: Verify the correctness of the load-bearing capacity analysis of the bottom truss chord joint for bearing of the side and middle members and bending of the dowel.

References: Nasonov S.B. Manual on design and analysis of building structures. – M: ASV Publishing House, 2013. – p. 116-118.

Initial data file:

Example 19.SAV;

report – Decor 19.doc.

Compliance with the codes: SNiP ІІ-25-80, SP 64.13330.2011.

Initial data from the source:

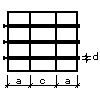

| с×h = 10×20 см | Section sizes of the timber chord |

| а×h = 5×20 см | Section sizes of steel gusset plates |

| d = 16 мм | Diameter of bolts |

| N = 80 кН | Tensile force in the chord |

| Material of the element: | pine |

| Grade of wood: | 2 |

| Steel grade of the gusset plates: | С235 |

| Operating conditions class: | 1 (А2 according to SNiP ІІ-25-80). |

DECOR initial data:

Importance factor γn = 1

|

Service factors |

|

|

Service factor for temperature and humidity operating conditions mВ |

1 |

|

Allowance for the temperature conditions of operation mТ |

1 |

|

Allowance for the duration of loading md |

1 |

|

Service factor under short-term loads mn |

1 |

|

Factor that allows for the effect of impregnation with protective substances mа |

1 |

Wood species - Pine

Grade of wood - 2

Non-glued timber section

Connection with cylindrical dowels

Dowel type - Steel

|

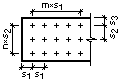

Arrangement of dowels – in-line

|

Symmetric joint

Number of design-glue-lines for one dowel - 2 |

Forces

N = 80 kN

Comparison of solutions:

|

Check |

Load-bearing capacity for bearing of the side member |

Load-bearing capacity for bearing of the middle member |

Bending of the steel dowel |

|

Theory |

80/102,4 = 0,781 |

80/128 = 0,625 |

80/81,73 = 0,979 |

|

DECOR |

0,781 |

0,625 |

0,979 |

|

Deviation, % |

0% |

0% |

0% |

Comment:

The necessary number of dowels in the given connection was determined in the theoretical solution of the problem in the source, and the joint was designed. In the result it was decided to put 6 dowels on each side of the joint and arrange them in two rows, and the distances between the dowel axes were determined: S1 = 11,2 cm, S2 = 5,6 cm and S3 = 4,8 cm. These parameters are used in DECOR for checking the connection.