Analysis of a Welded Connection between a Bar in Tension from Two Angles and a Gusset Plate

Objective: Check the mode for calculating welded connections.

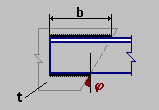

Task: Check the fillet welded connection between a bar in tension from two angles 75х8 and a gusset plate.

References: Steel Structures. In 3 v. — V. 1. Elements of Steel Structures/ Gorev V.V., Uvarov B.Yu., Filippov V.V. and others — M.: High school, 2004. p. 159-160.

Compliance with the codes: SNiP II-23-81*, SP 16.13330.2011, SP 16.13330.2017, DBN B.2.6-163:2010, DBN B.2.6-198:2014.

Initial data:

| t = 10 mm | thickness of the gusset plate |

| N = 425 kN | Longitudinal force |

| Run = 380 MPa | Steel С245 |

| Rwf = 220 MPa | CO2 semiautomatic welding with a Sv-08G2S wire, d = 1,2 mm |

| kf1 = 6 mm | Weld at connected leg |

| kf2 = 6 mm | Weld at free leg |

| Section | Angle 75х8 mm |

| lw1 = 175 mm | weld length along the free leg |

| lw2 = 80 mm | weld length along the connected leg |

Initial data file:

| Kristall1.10.doc — report |

KRISTALL initial data:

Steel: C245

|

Importance factor |

1 |

|

Service factor |

1 |

|

Group of structures according to the table 50* of SNiP II-23-81* |

1 |

|

Properties of welding materials: |

|

|---|---|

|

Characteristic resistance of the weld metal based on the ultimate strength, Rwun |

490 N/mm2 |

|

Design resistance of the fillet welds for shear in the weld metal, Rwf |

215 N/mm2 |

|

Type of welding |

Automatic and semiautomatic, diameter of the electrode wire not less than 1.4-2.0 mm |

|

Position of weld |

Flat |

|

Climatic region |

with temperature t > -40°C |

|

Type: |

Parameters: |

|---|---|

|

Section - Full assortment of GOST profiles.. Equal angle GOST 8509-93 L75x8 |

Weld at free leg = 6 mm

|

Internal forces:

N = 425 kN

|

Checked according to SNiP |

Check |

Utilization factor |

|---|---|---|

|

Sec.11.2 Formula (120) |

of the weld metal |

1.018 |

|

Sec.11.2 Formula (121) |

of the metal of the fusion border |

0.921 |

Comparison of solutions:

|

Check |

of the weld metal along the heel |

|

Source |

7,9 см / 8 см = 0,9875 |

|

KRISTALL |

1,018 |

|

Deviation, % |

3,0 |

|

Refined manual calculation (see comments) |

0,7133×425 / (2×0,7×0,6×16,5cm×21,50)=1,017 |

|

Deviation, % |

0,1 |

Comments

The difference in the results is due to the difference in the assumed values of the design resistance Rwf = 220 MPa (book) and Rwf = 215 MPa (design codes and KRISTALL). Moreover, the distribution of the external longitudinal force between the welds along the toe and heel of the angle is not specified precisely in the verification example, i.e. the longitudinal force in the weld along the heel is given as 70% of the external longitudinal force, and that along the toe is given as 30% of the force. The exact value of the longitudinal force acting in the welds along the heel is calculated as:

(bangle – y0)/bangle×N = 0,7133×N, where bangle – angle leg width, y0 – length of a perpendicular dropped from the center of mass of the angle to the respective external leg face.