Analysis of an Overlapping Bolted Connection of Steel Sheets with High Strength Bolts

Objective: Check the mode for calculating friction connections

Task: Check an overlapping connection of 500х12 mm sheets with high strength bolts from steel grade С245 for a shear force.

References: Steel Structures: Student Handbook / [Kudishin U.I., Belenya E.I., Ignatieva V.S and others] - 13-th ed. rev. - M.: Publishing Center "Academy", 2011. p. 165.

Compliance with the codes: SNiP II-23-81*, SP 16.13330, DBN B.2.6-163:2010.

Initial data file:

2.2.sav;

report — Kristall2.1.doc

Initial data from the source:

| N = 1000 kN | Shear force; |

| Ry = 240 MPa | Steel grade C245; Thickness of plates: two external – 8 mm, internal – 12 mm; |

| Rbun = 110 kN/cm2 | High strength bolts from 40H “select” steel; Diameter of bolts 20 mm, diameter of holes 23 mm; |

| γc = 1 | Service factor; |

| γb = 0,9 | Service factor of the friction connection; Method of cleaning the surfaces – flame treatment, without preservation; |

| μ = 0,42 | Coefficient of friction; |

| γh = 1,12 | Tightening control – by the nut rotation angle. |

KRISTALL parameters:

Steel: C245

|

Importance factor |

1 |

|

Service factor |

1 |

|

Service factor of members to be joined |

1 |

Diameter of bolts 20 mm

Steel: 40H "select"

Clearance 3 mm

Method of cleaning the surfaces to be joined: Flame treatment of two surfaces, without preservation

|

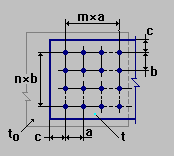

Type: |

Parameters: |

|---|---|

|

|

m = 1 |

Internal forces and moments:

N = 1000 kN

M = 0 kNm

Q = 0 kN

Manual calculation:

1. Design tension resistance of high strength bolts was calculated according to the following formula:

\[ R_{bh} =0.7R_{bun} =0.7\times 1100=770 \quad Н/мм^{2} \quad =77,0 \quad kN/cm^{2}. \]

2. Design force which can be resisted by each plane of friction:

\[ Q_{bh} =\frac { R_{bh} A_{bn} \mu} {\gamma_{h} }=\frac {77\times 2.45\times0.42}{1,02}=77,68 \quad kN, \]

where γh = 1,02 for flame treatment without preservation, when the difference between the nominal diameters of the holes and of the bolts is 3 mm, and the bolt tightening is controlled by the nut rotation angle.

3. Required number of bolts:

\[ n\ge \frac{N}{Q_{bh} \kappa \gamma_{b} \gamma_{c} }=\frac{1000}{77.68\times 2\times 0.9\times 1.0}=7,152. \]

Comparison of solutions:

|

Factor |

Friction force limit |

|---|---|

|

Manual calculation |

7,152/8 = 0,894 |

|

KRISTALL |

0,894 |

|

Deviation from the manual calculation, % |

0,0 |

|

|

|

|

Source |

0,893 |