Analysis of a Welded Connection with Fillet Welds at the Simultaneous Action of Longitudinal and Lateral Forces

l1=30 cm; l2=20 cm; l3=81cm

Objective: Check the mode for calculating welded connections

Task: Check the welded connection with fillet welds. The connection is loaded with longitudinal and lateral forces.

References: Manual to SNiP II-23-81. Welded Connections. 1984. p. 30 – 33.

Compliance with the codes: SNiP II-23-81*, SP 16.13330.2011, SP 16.13330.2017, DBN B.2.6-163:2010, DBN B.2.6-198:2014.

Initial data file:

| 1. when the weld leg is kf = 10 mm: | 1.3-1.sav; | report — Kristall1.3-1.doc |

| 2. when the weld leg is kf = 5 mm: | 1.3-2.sav; | report — Kristall1.3-2.doc |

Initial data:

| N = 100 kN | Longitudinal force |

| Q = 38 kN | Lateral force |

| Run = 370 MPa | Steel VSt3 |

| Rwf = 200 MPa, βf = 0,7 | Welding with coated E46 electrodes |

| γwf = γc = 1 | Service factors |

KRISTALL initial data when the weld leg is 10 mm:

Steel: C255

|

Importance factor |

1 |

|

Service factor |

1 |

|

Group of structures according to the table 50* of SNiP II-23-81* |

1 |

|

Properties of welding materials: |

|

|---|---|

|

Characteristic resistance of the weld metal based on the ultimate strength, Rwun |

45871.56 T/m2 |

|

Design resistance of the fillet welds for shear in the weld metal, Rwf |

20387.36 T/m2 |

|

Type of welding |

Manual |

|

Position of weld |

Flat |

|

Climatic region |

with temperature t > -40°C |

|

Type: |

Parameters: |

|---|---|

|

|

Weld leg = 10 mm

|

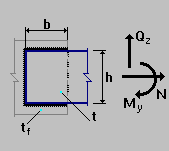

Internal forces and moments:

N = 100 kN

My = 30.78 kNm

Qz = -38 kN

KRISTALL initial data when the weld leg is 5 mm:

Steel: C255

|

Importance factor |

1 |

|

Service factor |

1 |

|

Group of structures according to the table 50* of SNiP II-23-81* |

1 |

|

Properties of welding materials: |

|

|---|---|

|

Characteristic resistance of the weld metal based on the ultimate strength, Rwun |

45871.56 T/m2 |

|

Design resistance of the fillet welds for shear in the weld metal, Rwf |

20387.36 T/m2 |

|

Type of welding |

Manual |

|

Position of weld |

Flat |

|

Climatic region |

with temperature t > -40°C |

|

Type: |

Parameters: |

|---|---|

|

|

Weld leg = 5 mm

|

Internal forces and moments:

N = 100 kN

My = 30.78 kNm

Qz = -38 kN

Comparison of solutions:

|

Weld leg, mm |

10 |

5 |

|

Check |

of the weld metal |

of the weld metal |

|

Source |

96,2/200 = 0,48 |

198/200 = 0,99 |

|

KRISTALL |

0,461 |

0,941 |

|

Deviation, % |

3,95 |

4,9 |

Comments:

The difference in the results is due to the inaccuracy made by the authors of the example in the design section of the weld. It should be also noted, that in the problem the force Q is transferred through the cantilever of 81 cm, therefore the moment М = 38 kN *0,81 m = 30,78 kNm is additionally specified in KRISTALL.