Analysis of a Welded Connection of Elements with Packings

Objective: Check the mode for calculating welded connections.

Task: Check the fillet welded connection between two strips in tension with packings.

References: Moskalev N.S., Pronosin J.A. Steel Structures. Handbook / M.: ASV Publishing House, 2010. p. 87-88.

Compliance with the codes: SNiP II-23-81*, SP 16.13330.2011, SP 16.13330.2017, DBN B.2.6-163:2010, DBN B.2.6-198:2014.

Initial data:

| 300х20 mm | Strip section |

| 250х12 mm | Packing section |

| Run = 360 MPa | Steel С235 |

| N = 1380 kN | Force |

| Rwf = 180 MPa | Manual welding with E42 electrodes |

| kf = 10 mm | Weld leg |

Initial data file:

1.7.sav;

report — Kristall1.7.doc

KRISTALL initial data:

Steel: C235

|

Importance factor |

1 |

|

Service factor |

1 |

|

Group of structures according to the table 50* of SNiP II-23-81* |

4 |

|

Properties of welding materials: |

|

|---|---|

|

Characteristic resistance of the weld metal based on the ultimate strength, Rwun |

410000 kN/m2 |

|

Design resistance of the fillet welds for shear in the weld metal, Rwf |

180000 kN/m2 |

|

Type of welding |

Manual |

|

Position of weld |

Flat |

|

Climatic region |

with temperature t > -40°C |

|

Type: |

Parameters: |

|---|---|

|

|

Weld leg = 10 mm

|

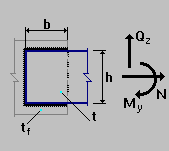

Internal forces and moments:

N = 1380 kN

My = 0 kN

Qz = 0 kN

|

Checked according to SNiP |

Check |

Utilization factor |

|---|---|---|

|

Sec.11.2 Formula (120) |

of the weld metal |

0.944 |

|

Sec.11.2 Formula (121) |

of the metal of the fusion border |

0.734 |

Comparison of solutions:

|

Check |

of the weld metal |

|

Source |

27,4 cm / 28/cm = 0,979 |

|

KRISTALL |

0,944 |

|

Deviation, % |

3,58 |

Comments:

In the example, the plates are cut in the shape of a fish, the theoretical length of the weld along the diagonal is 290 mm, one of the legs has the size of 260 mm, and the other – 290 – 260 = 30 mm. Therefore, the width of the plate is specified in KRISTALL as 2*30 mm = 60 mm to maintain the same length of the welds.