Strength and Stiffness Analysis of Main Beams of Complex Stub Girder Systems

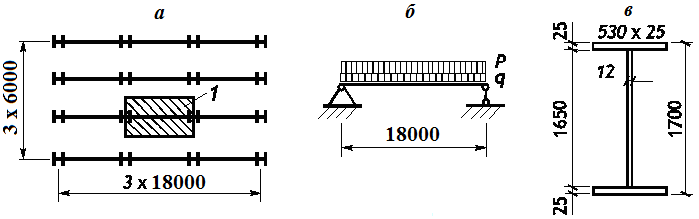

a – floor plan; b – design model of the main beam; c – beam section;

1 – load area

Objective: Check the mode for the beam analysis in the “Steel” postprocessor of SCAD

Task: Select a welded I-beam for the main beams with a span of 18 m in a normal stub girder system. The top chord of the main beams is restrained by the stringers arranged with a spacing of 1 m.

Source: Steel Structures: Student Handbook / [Kudishin U.I., Belenya E.I., Ignatieva V.S and others] - 13-th ed. rev. - M.: Publishing Center "Academy", 2011. p. 192.

Compliance with the codes: SNiP II-23-81*, SP 16.13330.2011, DBN B.2.6-163:2010.

Initial data file:

3.4 Beam_Example_3.4.spr;

report – 3.4 Beam_Example_3.4.doc

Initial data:

| а = 6 м | Spacing of main beams; |

| g1 = 1,16 kN/m2 | Weight of the floor plate and stringers; |

| p = 20 kN/m2 | Temporary (live) load; |

| qн = 127,099 kN/m | Total characteristic load on the beam; |

| q1 = 1,05*1,16 kN/m2 * 6 m*1,02 = 7,454 kN/m | Design permanent load (coefficient 1,02 allows for the self-weight of the main beam); |

| q2 = 1,2*20 kN/m2 * 6 m = 144,0 kN/m | Design live load; |

| l = 18 m | Main beam span; |

| Ry = 23 kN/cm2 Rs = 0,58*23=13,34 kN/cm2 |

Steel grade C255 with thickness t>20 mm; |

| [ f ] = l/400 = 45 mm | Limit deflection; |

| bp×tp = 530×20 mm | Section of the bearing stiffener; |

| kp = 6 mm | Fillet weld leg in a welded connection between a bearing stiffener and a beam; |

| γc = 1 | Service factor; |

| Wy = 27153,85 cm3 | Geometric properties for a welded I-section with flanges 530×25 mm |

| Iy = 2308077,083 cm4 | and a web 1650×12 mm; |

| Sy = 15180,625 cm3. |

SCAD Results. STEEL Postprocessor:

[Element No 3] Forces

|

N Max. 0 T Max. 0 T |

My Max. 625,27 T*m |

Mz Max. 0 T*m Max. 0 T*m |

|

Mk Max. 0 T*m Max. 0 T*m |

Qz Max. 69,47 T Max. 0 T |

Qy Max. 0 T Max. 0 T |

|

|

Length of the bar 4,5 m |

|

[Element No. 3] Deflections

|

X

|

Y

|

Z Max. -43,54 mm |

|

|

Length of the bar 4,5 m |

|

Analysis complies with SNiP II-23-81*

Structural member main beam

Steel: C255

Member length 18 m

Limit slenderness for members in compression: 180

Limit slenderness for members in tension: 300

Service factor 1

Importance factor 1

Effective length factor XoZ -- 1

Effective length factor XoY -- 1

Length between out-of-plane restraints 1 m

Section

|

Results |

Check |

Utilization factor |

|---|---|---|

|

Sec.5.12 |

Strength under action of bending moment My |

0,98 |

|

Sec.5.12,5.18 |

Strength under action of lateral force Qz |

0,56 |

|

Sec.5.24,5.25 |

Strength under combined action of longitudinal force and bending moments, no plasticity |

0,98 |

|

Sec.5.15 |

Stability of in-plane bending |

0,98 |

|

Sec.6.15,6.16 |

Limit slenderness in XoY plane |

0,52 |

|

Sec.6.15,6.16 |

Limit slenderness in XoZ plane |

0,08 |

Utilization factor 0,98 - Strength under action of bending moment My

Manual calculation (SNiP II-23-81*)

1. Maximum bending moment and shear force acting in the design sections of the beam:

\[ M_{\max } =\frac{q_{\Sigma } l^{2}}{8}=\frac{\left( {7,454+144} \right)\cdot 18,0^{2}}{8}=6133,887 \quad kNm. \] \[ Q_{\max } =\frac{q_{\Sigma } l}{2}=\frac{\left( {7,454+144} \right)\cdot 18,0}{2}=1363,086 \quad kN. \]

2. Necessary beam section modulus:

\[ W_{nes} =\frac{M_{\max } }{R_{y} \gamma_{c} }=\frac{6133,887\cdot 100}{23}=26669,074 \quad cm^{3}. \]

3. Maximum tangential stresses in the support section of the beam:

\[ \tau_{\max } =\frac{Q_{\max } S_{y} }{I_{y} t_{w} }=\frac{1363,086\cdot 15180,625}{2308077,083\cdot 1,2}=7,471 \quad kN/cm^{2}. \]

4. Maximum deflection occurring in the middle of the beam span:

\[ f_{\max } =\frac{5}{384}\cdot \frac{q_{н} l^{4}}{EI_{y} }=\frac{5}{384}\cdot \frac{127,099\cdot 18,0^{4}}{2,06\cdot 10^{5}\cdot 10^{3}\cdot 2308077,083\cdot 10^{-8}}=36,539 \quad mm. \]

5. Conditional limit slenderness of the compressed beam chord:

\[ \bar{{\lambda }}_{ub} =0,35+0,0032\frac{b_{f} }{t_{f} }+\left( {0,76-0,02\frac{b_{f} }{t_{f} }} \right)\frac{b_{f} }{h_{f} }=0,35+0,0032\frac{530}{25}+\left( {0,76-0,02\frac{530}{25}} \right)\frac{530}{1675}=0,524. \]

6. Conditional actual slenderness of the compressed beam chord:

\( \bar{{\lambda }}_{b} =\frac{l_{ef} }{b_{f} }\sqrt {\frac{R_{y} }{E}} =\frac{1000}{530}\sqrt {\frac{230}{2,06\cdot 10^{5}}} =0,063<\bar{{\lambda }}_{ub} =0,524 \) – the stability check is not required.

Comparison of solutions:

|

Factor |

Manual calculation |

SCAD |

Deviation, % |

|---|---|---|---|

|

Strength under action of lateral force |

7,471/13,34 = 0,56 |

0,56 |

0,0 |

|

Strength under action of bending moment |

26669,074/27153,85=0,982 |

0,982 |

0,0 |

|

Stability of in-plane bending under moment |

– |

0,982 |

0,0 |

|

Maximum deflection |

36,539/45 = 0,812 |

43,54/1,1916/45= 0,812 |

0,0 |

Comments:

The check for the stability of in-plane bending of the beam was performed in the computer-aided calculation according to the codes at φb = 1,0.